HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

product category

Add:North Side, Haomen Road, Yutian County, Tangshan City, Hebei Province, China

Sale Mobile:13931543095

Tel:0315-6117767

1.Paper Feeding Unit

The belt vacuum feeding mechanism is adopted in the machine, which is economical and practical. Meanwhile, keep the feeding stable, high-speed, accurate and non-slanting paper can be ensured. The belts for paper feeding can be adjusted individually and each vacuum bellows can be closed separately. The paper can be fed neatly by side-mounted pneumatic flapping device. The Siemens motor is adopted as main motor, and the glue coating method under the knurling wheel is adopted for the coating part, so that the glue is evenly distributed, no leakage coating phenomenon, and the glue is saved. Meanwhile, the rubberizing speed of the rubberizing wheel is synchronized with the main machine, which reduces the friction of the rubber wheel and the cardboard and the life of the rubber wheel can be extended.

2.Folding Gluing Unit

The secondary Pre-folding wheel is used for the folding part to ensure that paper feeding is stable and non-slip. The wall board is processed by the machining center so that the dimensional accuracy can be ensured. The differential speed of upper and lower belts can automatically be adjusted in order to ensure the folding and alignment.

3.Arrangement Unit

The paper-correcting device is used to perform secondary compensation and correction of the box not in right place, eliminating the “scissors opening” and making the nail box more perfected.

4. Stitching Unit

There are three Japanese Mitsubishi high-power servo motors, Japan's Mitsubishi's latest programming controller(PLC computer system), Weinview touch screen control system, to ensure that the electrical operation is accurate, the running nail head uses Italian parts, which can ensure the mechanical operation is stable and durable. The centralized lubrication system is concentrated significantly, so that the wear of the lubricating parts can be reduced, which can effectively extend the life of the nail head components by 60-80% and improve the maintenance efficiency. The speed of the running nail head is faster and the appearance is more beautiful, which can effectively improve the quality of the finished nailing box. The advantage of the machine head is that there are few adjustable places, and the size of each part is mainly ensured by the precision of the parts.

5.Delivery Unit

The secondary pre-folding wheel is used for the folding part to ensure that paper feeding is stable and non-slip. The wall board is processed by the machining center so that the dimensional accuracy can be ensured. The differential speed of upper and lower belts can automatically be adjusted in order to ensure the folding and alignment.

| Model | AFS-2500 |

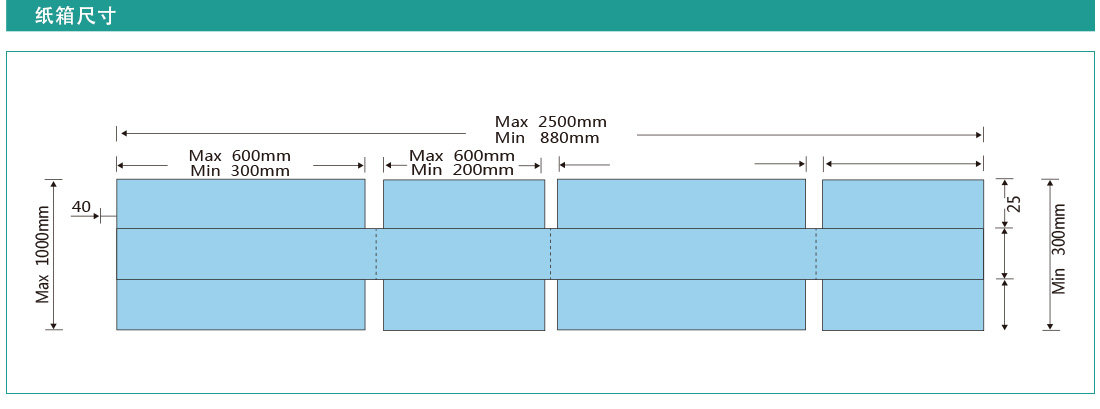

| Max. Paper Width | 1200mm |

| Min. Paper Width | 300mm |

| Machine Width | 4.2m |

| Machine Length | 14.2m |

| Max. Paper Length | 2500mm |

| Min. Paper Length | 880mm |

| Max. TS Width | 40mm |

| Power Required | 28.5Kw |

| Installation Area | 13900×4200mm |

| Stitching Speed(Nails/Min) | 1100 |

| Machine Weight | 9T |

| Pitch of Nails for Single Nail and Double Nails (Min.-Max.) | 30-90mm |

| Pitch of Nails for Intensive Nail(Min.-Max.) | 30-70mm |

| Paste Speed | 130 Meter/Min |

| Air Pressure | 0.6-0.8Mpa(Buyer provide) |

Sale Mobile

Tel

Applets