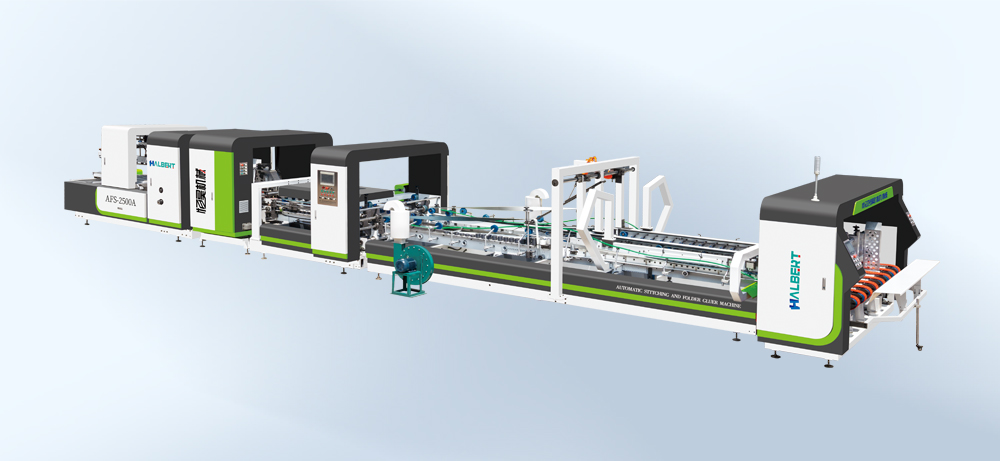

HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

product category

Add:North Side, Haomen Road, Yutian County, Tangshan City, Hebei Province, China

Sale Mobile:13931543095

Tel:0315-6117767

01.The biggest characteristic of this machine is computer operation which is simple to use, stable quality, high speed and greatly saved labor.

02.This is a multifunctional integrated machine which can nail box and paste box. It also can complete paste box and the nail box at one time.

03.It can complete setting up step in 3-5 minutes which means it can start a mass production (This machine has order memory function).

04.One key switch functions of the paste box and the nail box which is an original creation in the home market.

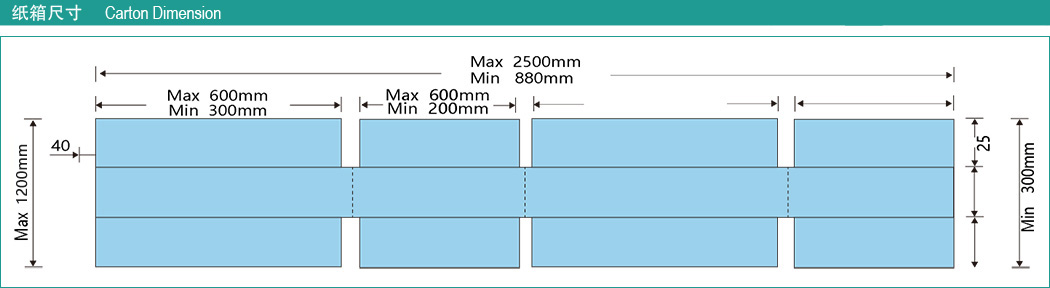

05.Suitable paperboard nailed of three, five, single board, A, B, C, and AB corrugated cardboard.

06.A side flapping device for paper feeding ensures the delivery of paper smoothly.

07.A box with no bottom but a lid can also be nailed.

08.Nailed range: the minimum nail distance is 40 mm and the maximum nail distance is 500 mm.

09.Maximum nailed speed of nail head: 1100 nails / minutes.

10.Take three nail speeds as an example, the maximum speed is 110 pieces per minute.

11.It can be done automatically for paper folding, correction, nail box, paste box, counting and stacking output.

12.Single nail and double nail can be adjusted freely.

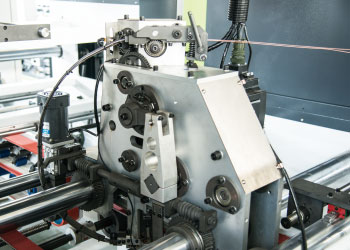

13.Adopting swing nail head which can achieve the small power consumption, high speed, more stable, and improved the quality of the nail box effectively.

14.Adopting a paper correction device to compensate for two times and to correct the place of the box, and eliminate the scissors mouth, and make the box stitching more perfect.

15.The automatic wire feeder can detect the nail wire detection, broken wire and run out detection.

| Model | AFS-2500A |

| Max. Paper Width | 1200mm |

| Min. Paper Width | 300mm |

| Machine Width | 4.2m |

| Machine Length | 16m |

| Max. Paper Length | 2500mm |

| Min. Paper Length | 880mm |

| Max. TS Width | 40mm |

| Power Required | 28.5Kw |

| Installation Area | 16000×4200mm |

| Stitching Speed(Nails/Min) | 1100 |

| Machine Weight | 12.5T |

| Pitch of Nails for Single Nail and Double Nails (Min.-Max.) | 30-90mm |

| Pitch of Nails for Intensive Nail(Min.-Max.) | 30-70mm |

| Paste Speed | 130 Meter/Min |

| Air Pressure | 0.6-0.8Mpa(Buyer provide) |

01

01

Less power consumption, higher speed, more stable performance and it can highly improve the stitching and gluing quality.

02

02

To completely eliminate fishtail shape box problem, this unit will make re-correction the position of creasing line. It highly Improved the product qualification rate.

03

03

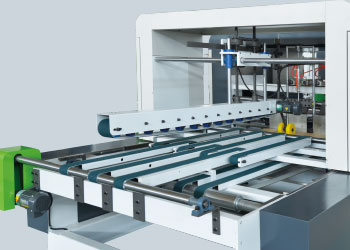

The finished products are counted, stacked and collected automatically. Stacking speed up to 130m/min.

04

04

Creasing again when corrugated board running to keep the folding more accurate and tidier without paper broken.

05

05

Adopt the electric control system, to ensure all the nail delivery more accurate in high speed.

06

06

Adopt the servo motor and synchronous belt chasing system to highly reduce the paper damage, make re-correction for the corrugated board position, completely eliminate the “scissors mouth” shape box problem. This unit adopts HENGHAO owned patented technology.

07

07

Fully computer control, automatic gauge adjustment system, one-button adjustment.

08

08

Fully computer control, automatic gauge adjustment, one-button adjustment.

09

09

Linear sliding hangers are added to the front and back of the upper wallboard, and four-point cylinder locking devices are added to the front and back position.

10

10

There are 8 separate suction devices in the feeding unit, which can be individually switched to control the wind force to ensure the accurate carton feeding.

Sale Mobile

Tel

Applets