HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

HALBERT has been committed to the R&D and manufacture ofAutomatic Stitching and Folder Gluer Machine for more than ten years.

product category

Add:North Side, Haomen Road, Yutian County, Tangshan City, Hebei Province, China

Sale Mobile:13931543095

Tel:0315-6117767

1.Device for Paper Feeding

The belt vacuum feeding mechanism is adopted in the machine, which is economical and practical. Meanwhile, the stable, high-speed, accurate and non-slanting paper can be ensured. The belts for paper feeding can be adjusted individually and each vacuum bellows can be closed separately. The paper can be fed neatly by side-mounted pneumatic flapping device. The Siemens motor is adopted as main motor, and the glue coating method under the knurling wheel is adopted for the coating part, so that the glue is evenly distributed, no leakage coating phenomenon, and the glue is saved. Meanwhile, the rubberizing speed of the rubberizing wheel is synchronized with the main machine, which reduces the friction of the rubber wheel and the cardboard and the life of the rubber wheel can be extended.

2. Device for Folding

The secondary pre-folding wheel is used for the folding part to ensure that paper feeding is stable and non-slip. The wall board is processed by the machining center so that the dimensional accuracy can be ensured. The differential speed of upper and lower belts can automatically be adjusted in order to ensure the folding and alignment.

3. Device for Paper Receiving

The automatic tapping device is equipped with automatic point function, which is more convenient.

| Model | AFSH-2500 |

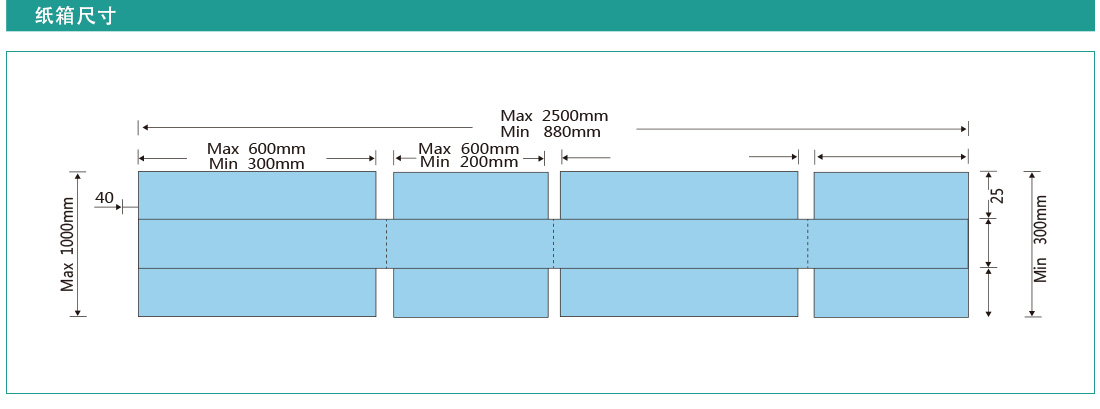

| Max. Paper Width | 1000mm |

| Min. Paper Width | 300mm |

| Machine Width | 4.2m |

| Machine Length | 12m |

| Max. Paper Length | 2500mm |

| Min. Paper Length | 880mm |

| Max. TS Width | 40mm |

| Installation Area | 10000×4200mm |

| Machine Weight | 6.5T |

| Paste Speed | 130 Meter/Min |

| Air Pressure | 0.6-0.8Mpa(Buyer provide) |

| Power Required | 13Kw |

Sale Mobile

Tel

Applets